Hucclecote Model Railway Show

At Hucclecote Methodist Church

June 2021

Barnwood Model Railway Club

Web-site http://www.barnwoodmodelrailwayclub.org.uk/

YouTube channel at https://www.youtube.com/channel/UCTHEEL4ih2BwdH0qXlzbghQ

Barnwood Model Railway Club was founded in late 2001 after the St Lawrence Church Parish Centre was opened in 2001. Located in Church Lane, Barnwood Gloucester; this venue’s meeting rooms have provide the essential space and Tea making facilities required to build and prototype the clubs model railway boards ever since then.

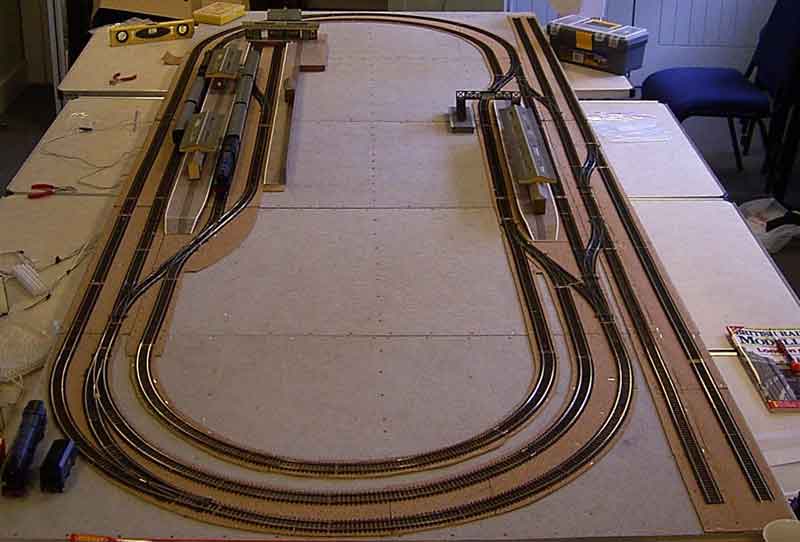

Figure 1: BMRC 10’ x 4’ Board on 05/06/2010.

Flying Scotsman on approach to Point No 15.

The BMRC’s founding member, the Rev. Bob Coates, gathered together the original 9 members and initially the club met together in each other’s front rooms to discuss the design of the Clubs very first layout.

This discussion phase lasted until 2003 while we accumulated subs to pay for building materials and to finalise the debate about having a “round and round” or a “backwards and forwards” track layout.

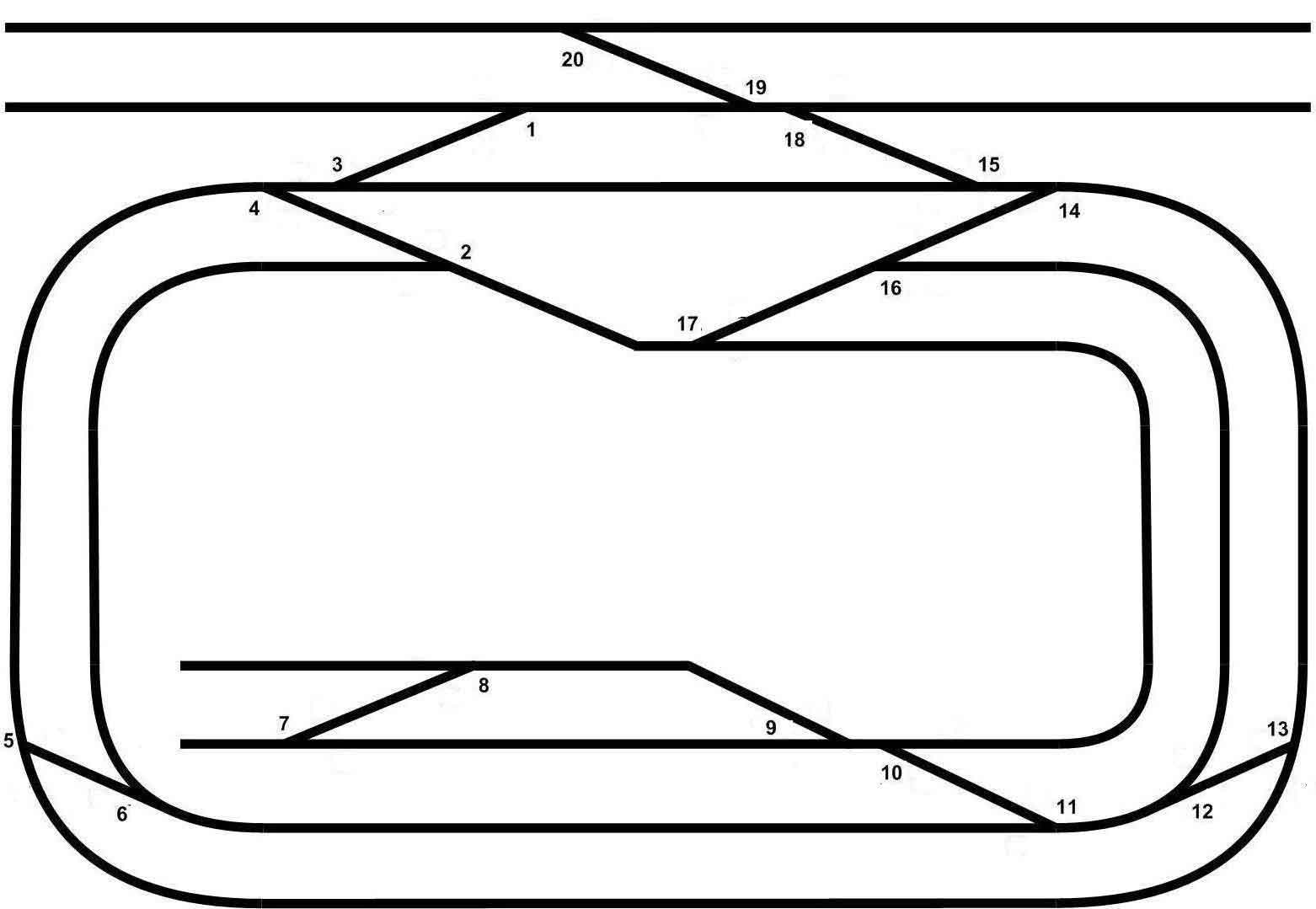

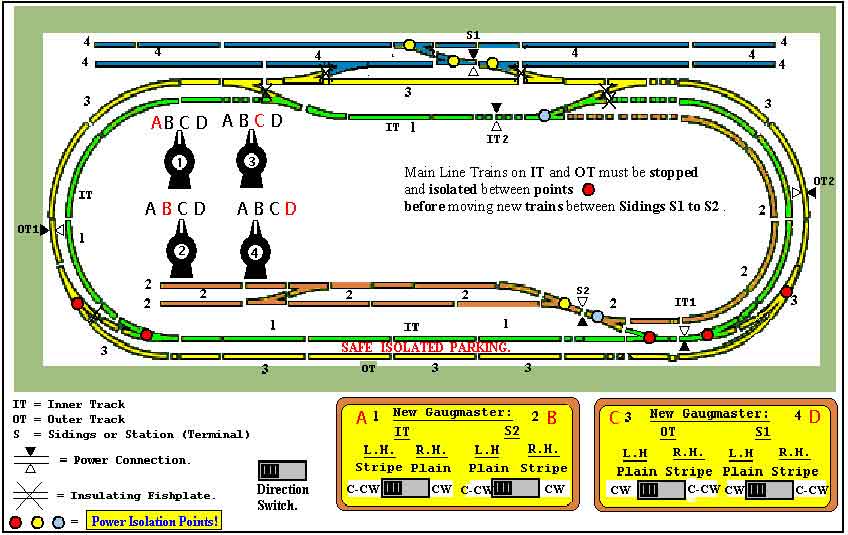

The final design shown in Figure 2 actually accommodated both requirements with the boundaries between the two highlighted by point motor locations 3, 15, 11 and 17. Figure 3 shows that construction was well under way by late 2004. Figures 3 to 7 show the slow but steady progress in track laying and scenery construction up to 2009.

Figure 2: BMRC 10’ x 4’ Board Track Design as used on Point Motor Control Box.

Figure 3: The BMRC 10’ x 4’ Model Railway Board: 28th January 2004

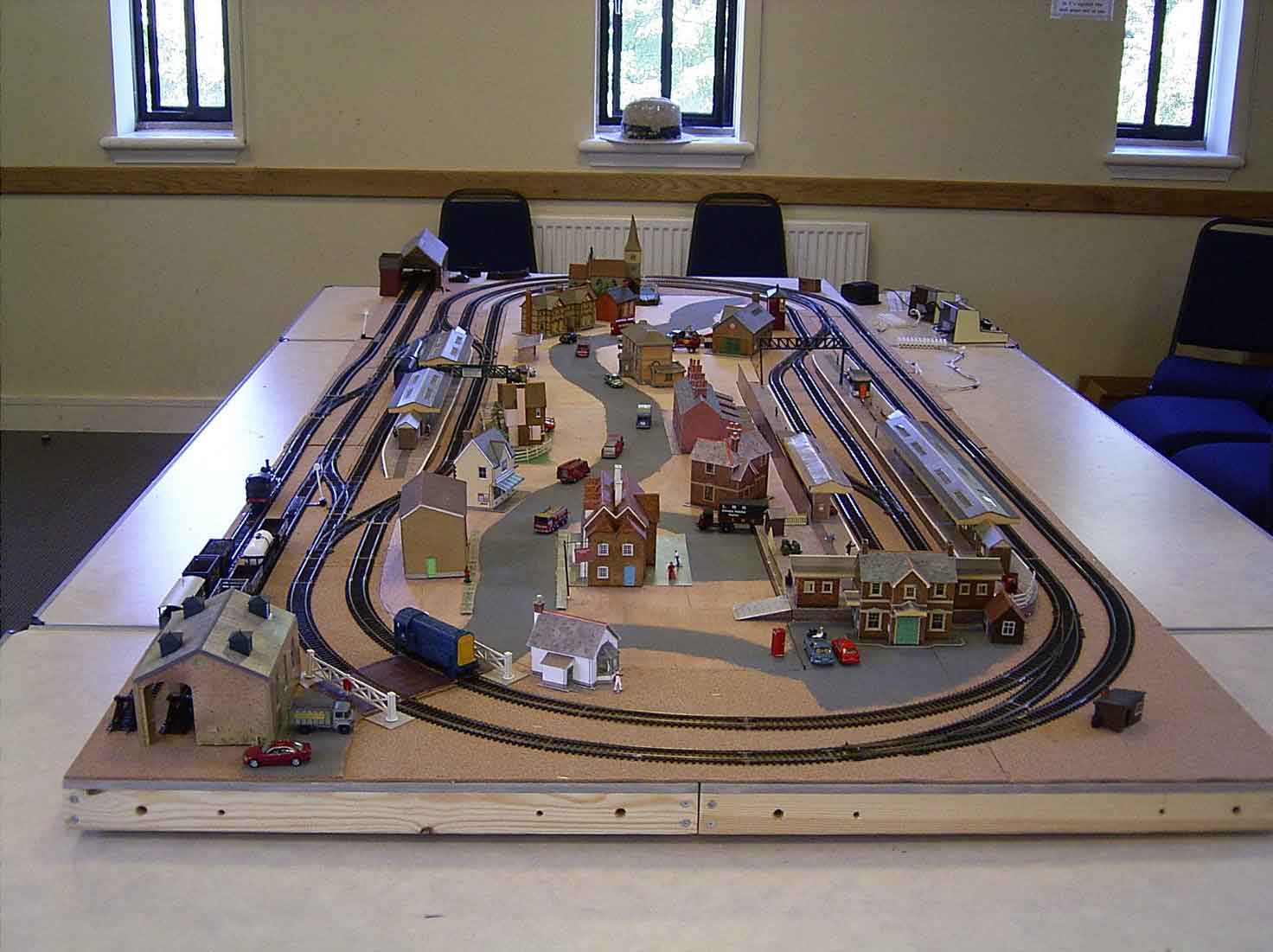

Figure 4: 25_02_2006

Figure 6 (right): Metcalfe buildings and shops 17/05/2008

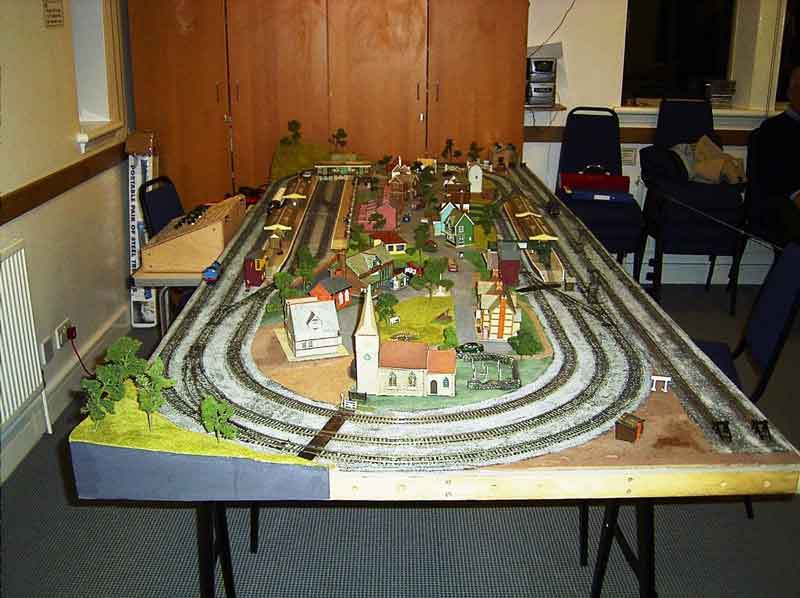

Figure 7: Fully ballasted board with Control Panel on 31/05/2009 Barnwood Fun Day.

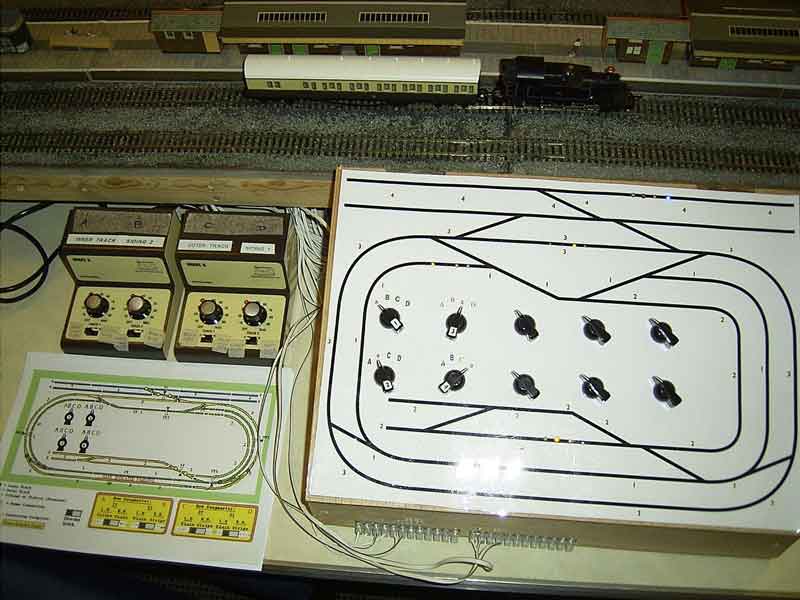

Figure 8: Gaugemaster D Dual Controllers and Point Motor Remote Control Panel.

By 2009 we had also completed the remote control of the 20 surface mounted point motors. We built a “cab wiring” control box and panel allowing the switching of any of the four available power outputs to any of the four running sections/loops. The panel also included stud and stylus “contact control” of the point directions.

Figure 9 illustrates the Yellow(3) and Green(1) Outer and Inner Loop respectively and the Orange (2) Terminal Station lines and shunting that share a platform with the Main Line between Point Motors 6 and 11. Finally some rolling stock parking and extra shunting was provided by the sidings blue (4).

Figure 9: Demonstration Day Driving Instructions (Aid de memoir?)

Using this Control panel allows a train to be transferred from the Terminus Station, Section 2,

through the inner and outer loops to Storage sidings in section 4 with a single controller.

Remembering that this was the clubs first ever board we waited a few years before we actually ballasted the track. This allowed us to tweak the layout a little without having to damage the base boards or the cork top surface covering the grey Sundeala material. This did not prevent us from running trains at our meetings or at our Annual October Open Day.

The boards 10’ length provides two main line stations and plenty of scope to exercise longer configurations of freight or passenger coaches. I have seen 9 Mk2 BR Blue and Grey Coaches (some borrowed) pulled by a single Lima Class 37 Diesel Locomotive. This board along with the more recent 8’ x 4’ “industrial” board have very much become our two main attractions at our Open Days in St.Lawrence Parish Centre. (See website for dates.).

The scenery on the 10’ board provides many photo and video vantage points from which to observe and record your favourite rolling stock. You can view trains passing over level crossings, passing hills, the village Church and School and of course you need shops and a garage to repair and fuel those new-fangled internal combustion engines. The central road from one end of the board to the other and its surrounding village dwellings and railway workers cottages resides on removable plywood sections to aid storage.

Regrettably the board is too large to exhibit beyond the Church Centre. Constructed of 2’ x 4’ panels made from 2” x 1” batons and Sundeala board with a topping of 2.5mm cork the board is stored as two sections of 4’x4’ and 6’ x 4’ that don’t fit into a Family Estate car …yet.

The board would be described as 12v Analogue although club and guest members have been known to run DCC trains on our track and have successfully exercised the various starting, stopping and idling sound effects.

In addition to the 10’ board the club has also constructed two other boards more recently.

The first of these is our Folding Board, an exhibition friendly board that can fit into an average sized family car. This board has been named “Barnwood Halt” pay homage to both where it was made and the desire for a local station in the area. Barnwood Halt and Barnwood Junction stations still serve to link opposite ends of this quiet residential village. Though never yet connected to the main line various plans for a “new Barnwood Station” have come and gone over the decades. The Church with its tower dominates one end of this, visionary, main shopping street. This pleasing interactive 4’ x 6’, 1:72 scale, model railway has been continually redeveloped through several iterations and will fold in two to enable transportation via a family estate or Hatch back size car. In 2018 we created a new fiddle yard connected to the layout via a new siding that allows access to interchangeable rolling stock. You may also notice a few new or relocated buildings some built and kindly donated to the Club by members of the parish of St. Lawrence Barnwood. While this portable 4’x 6’ display has allowed us to support various local Church and School fund raising events the BMRC is also building a new 8’ x 4’ industrial board to add to an existing 4’ x 10’ model railway which are worked on and run in St. Lawrence Church Centre.

Figure 10: The Folding Board “Barnwood Halt”

The second of these is the Industrial Board, an 8+2’ board that breaks easily apart into an 8’ and 2’ board for storage.

Figure 11: Industrial board during construction and early testing

The industrial board was commissioned in 2014 following the success of the folding board and was designed to use a modern approach to track control. Over the years the design has been incrementally improved to the point now where it is driven entirely by a Raspberry Pi and uses a GUI point and click style of control written in Python.

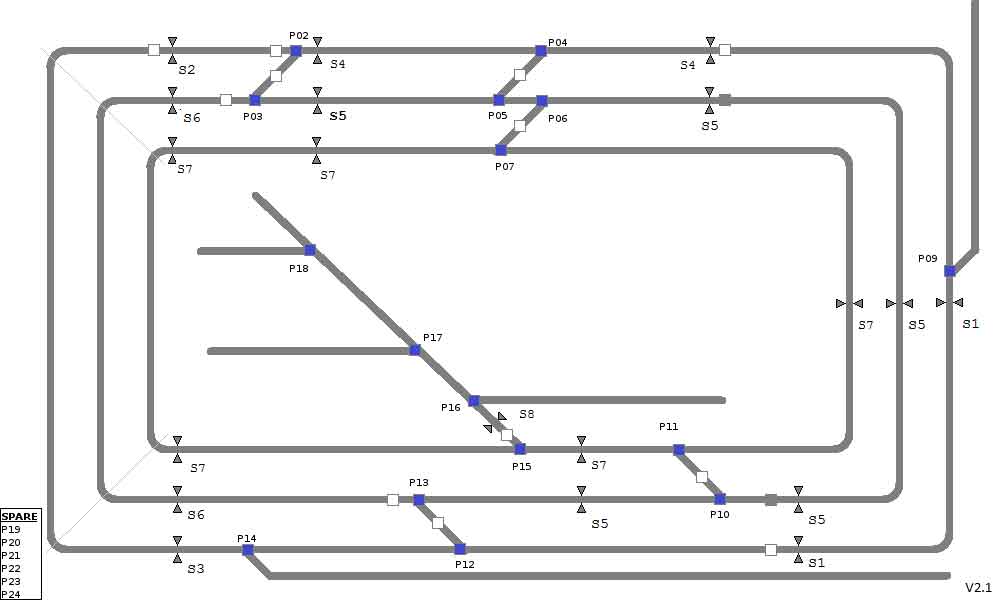

Figure 12: The logical layout of the Industrial board used by the control software

There are four track circuits that are independently controlled. The first of these is a shunting yard in the middle of the board with three spurs, this circuit connects via set of points to the inner loop. The second circuit controls the inner loop and allows a locomotive to cross over to the middle loop at the top and bottom of the board. A third circuit controls the middle loop, also allowing a cross over to the outer loop in three places. The fourth circuit controls the outer loop and has two sidings at the bottom of the board and right of the board to store locomotives and carriages temporarily.

To control the board the operator simply selects the direction of travel on the circuit they desire, then dials in the speed from the hand-held box, or via the GUI. The Raspberry Pi integrated into the underside of the board then takes care of all physical control of the locomotive. To toggle the direction of a point the operator simply clicks on the point position on the GUI and it is changed. To aid the operator in understanding what is happening on the board colour coding is used to indicate both the direction of a circuit and the position of a point. In addition, because the Raspberry Pi control both the speed, direction of a locomotive and the points it is possible to place a locomotive in one of the sidings then using a pre-defined sequence it will be driven around each of the loops and into the shunting area with no human interaction!